There is a list of components which we will be using in Brain controlled robotic project depending upon its mechanical structure and electronic way of operating it using different technologies.

The task which we are performing in our project can be performed through many different ways but we have selected and used the specific design and components depending upon the following factors.

Cost efficient

Availability

User friendly

As discuss in the first chapter of “beginning” we will be using following components in our project

Arduino:

Is an open source platform which can sense and control more of the physical world based on a simple microcontroller board. Arduino can be used to develop interactive objects, taking inputs from a variety of switches or sensors and controlling a variety of objects e.g. lights, motors and other physical outputs.

The Arduino programming language is an implementation of wiring, a similar physical computing platform, which is based on the processing multimedia programming environment.

There are many other microcontrollers available in market for physical computing Net media’s BX-24, phidgets, MIT’s handy board etc and many others offer similar functionality. Arduino also simplifies the process of working with microcontrollers, but it offers some advantages for teachers and students over other systems.

Arduino board is relatively inexpensive compared to other microcontroller platforms.

The arduino programming environment is easy to use for beginners yet flexible enough for advanced users to take advantage of as well.

The arduino software is published as open source tools available for extension by experienced programmer’s .The language can be expanded through C++ libraries.

Arduino Mega 2560:

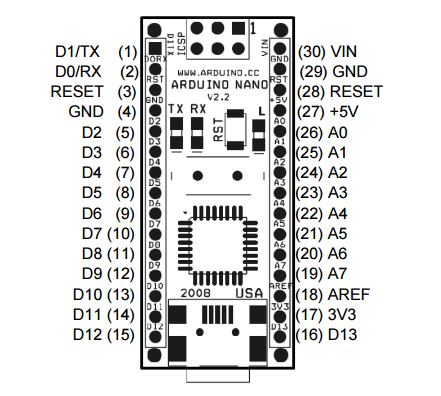

Pins configuration:

Figure 3.2

Figure 3.2

D0-D13:

The pins 1-2 and 5-16 are named as D0-D13 are I/O digital input/output from port 0 to 13.

Reset:

The pins 3 and 28 are inputs and performs the operations of reset.

Ground:

The 4 and 29 PWR pins which performs the operation of supply ground.

3V3:

It is an output which gives the +3.3v.

AREF:

Pin 18 named as AREF is the input pin which is the ADC refrence.

A7-A0:

The pins 19-26 named as A7-A0 are the analog input channel from 0 to 7.

+5V:

Pin 27 is the input or output which gives +5v output from on board regulator or +5v input from external power supply.

Vin:

The pin no 30 is the input supply voltage.

3.1.2 Arduino Mega:

(Front view Figure 3.3)

(Front view Figure 3.3)

(Back view Figure 3.4)

(Back view Figure 3.4)

The arduino Uno is a microcontroller board based on the Atmega328.It has 14 digital input/output pins which 6 can be used as PWM outputs,6 analog inputs, a 16 MHz ceramic resonator, a USB connection ,a power jack an ICSP header and a reset button. It contains everything needed to support the microcontroller simply connect it to a computer with a USB cable or power it with a AC to DC adapter or battery to get start.

Pins configuration:

Figure 3.5

Figure 3.5

Serial:

Pin 0 and 1used to receive (RX) and transmit (TX) TTL serial data.

External Interrupts:

Pins 2 and 3 can be configured to trigger an interrupt on a low value a rising or falling edge or a change in value.

PWM:

Pins 3, 5, 6, 9, 10 and 11 provide 8-bit PWM output with the analog write () function.

SPI:

SPI 10 (SS), 11(MOSI), 12(MISO),13(SCK) these pins support SPI communication using the SPI library.

LED:

There is a built in LED light at pin 13 when the pin has high value the light is on and when the pin has low value it would be off.

A0-A5:

The arduino Uno has 6 analog inputs named as A0 to A5 each of which provides 10 bits of resolution e.g.1024 different values.

TWI:

A4 or SDA pin and A5 or SCL pin performs TWI communication using wire library.

AREF:

This pin is the reference voltage for the analog inputs.

Reset:

Bring this line low to reset the arduino. Typically it is used to add a reset button to shields which block the one on the board.

DC Motors:

DC motor is a type of motor which converts direct current electrical power into mechanical power. There are many types of DC motors. One which we are using in our robotic arm is servo motor.

Figure 3.6 : Simple DC motor

Servo motors:

These are mechanical devices which are used to move output shaft, which is attached to servo wheel or arm. These are mostly used for position, velocity and torque control. Usually the shaft can move up to 180 degrees of angle.

Figure 3.7

A main part of servo motor is a DC motor inside it. It also contains a potentiometer which is known as position sensor, a gear system and control electronics.

Control circuit has electronic components generally having an oscillator and controller which receives signal from sensor and signal activates the direction of the motor necessary to the position shaft in required position.

Figure 3.8

It has 3 wires. One is for power, one is for ground and one is for PWM. By sending a coded signal, we can have any position of the shaft of servo motor. It can be positioned to specific angular positions and it will remain at that position until the coded signal exists. By changing the code, we can change angular position of shaft.

Servos which we are using have 13KG/cm operating torque. It works at 100mA current. Voltage used can be from 3 to 7.2V. Operating speed is 0.17 seconds per 60 degrees at 4.8V and 0.13 seconds per 60 degrees at 6V.

Figure 3.9: External View of Servo motor

Micro servo motor:

Micro Servo motor is used in the wrist. Its weight is 9g. Operating torque is 1.6KG/cm. It has plastic gear. It uses 3.5 to 6V.

Figure 3.10: Micro Servo motor

How does a servo motor work?

DC motor moves the gear system with large reduction ratio. The shaft imposes force on load and acts on the axis of a feedback potentiometer. Potentiometer senses position of axis and sends corresponding voltage to operational amplifier. Voltage compared to input voltage determines the desired position of a shaft producing voltage in output of comparator. Voltage powers motor such that a shaft moves in important direction to align with angle that is equal to the voltage applied to input.

Why we use servo motors:

We use it because it gives best accurate results.